Recycling at

Plastima Used Machinery is also the partner when it comes to recycling. We have a nice selection of used recycling machines for the plastics industry. You can also come to us for maintenance on your used recycling machine. In addition, we are available for service & maintenance questions.

Plastima Used Machinery is the partner when it comes to used recycling machines. We always have renowned brands such as Amis ZERMA, TECNOVA, Herbold and RAPID in stock.

RECYCLING

USED RECYCLING MACHINES

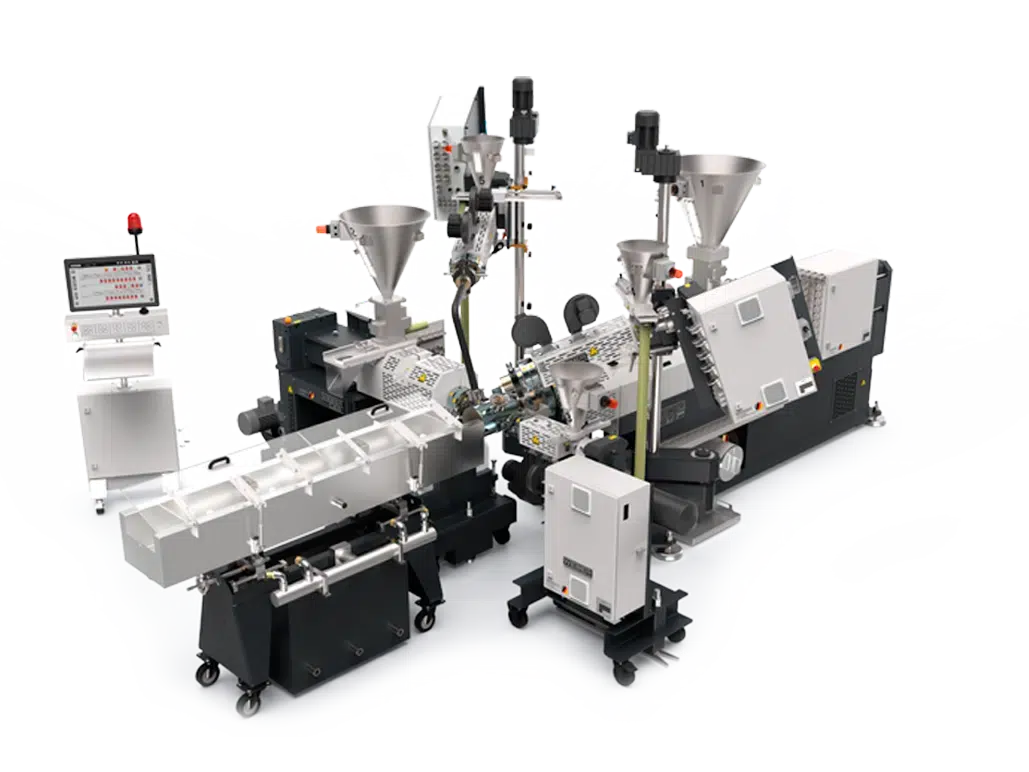

For recycling plastic out and waste, Plastima Used Machinery has several used machines in stock. Recycling equipment can include machines such as shredders and grinding mills for reducing the plastics. But we also have regular equipment for other recycling techniques such as regranulation (extruders), melt filtration and granulation. Of course, we would like to invite you to come and see our machines in our warehouse in Breda.

Didn't find what you were looking for?

No worries! Describe your (machine) requirement(s) here, we will dive into the market for you!

Why P.U.M. is your partner:

70 years of experience

Specializing in extrusion, recycling and injection moulding

The best brands

We work with the best brands in the market on an exclusive basis

Reliable & transparant

With a team of fourteen experts at your service

Used plastic recycling machines

All around us is plastic. From plastic soda bottles and plastic grocery bags to your plastic ID card, we see and use plastic every day. Much of this plastic comes from materials such as petrochemicals. Plastic can litter and pollute the environment. So it makes sense to reuse and reprocess plastic to avoid waste. Therefore, recycling plastic on used plastic recycling machines is a sustainable option in plastic production.

Recycling machines for used plastics play a crucial role in converting discarded plastics into reusable materials, and they include several components to accomplish this task. At the beginning of the recycling process, a conveyor belt transports the plastic waste into the machine. This is followed by a shredder or crusher, which breaks down large pieces of plastic into smaller, manageable sizes. Shredders usually use rotating blades, while crushers may use compression techniques.

Once the plastic is shredded, it must be cleaned often to remove contaminants such as dirt, food scraps and labels. This is where the wash tank comes in. After washing, a separation tank is used to separate different types of plastic based on their density. Some processes also use air classification systems or electrostatic separators for this purpose.

After washing and separation, the plastic must be dried before further processing. This is done using a dryer, which can range from a simple heated chamber to a more complex system. The dried plastic flakes are then melted and formed into a consistent shape, usually pellets, in the extruder. In this process, the plastic is heated and pushed through a die.

After the extrusion process, the continuous plastic strand is cut into pellets by a pelletizer, giving them a more convenient shape for the production of new plastic products. The entire operation is managed and monitored through a control panel that allows operators to adjust settings and oversee the recycling process.

In addition, some machines are equipped with a cooling system to maintain an optimal temperature during the recycling process, preventing plastic degradation. Finally, a collection system collects the final recycled product, whether flakes or pellets, and stores it until it can be transported for further processing or production. Together, these components provide an efficient and effective recycling process, converting plastic waste into valuable raw materials for new products.